magazine_ Article

A month of ice

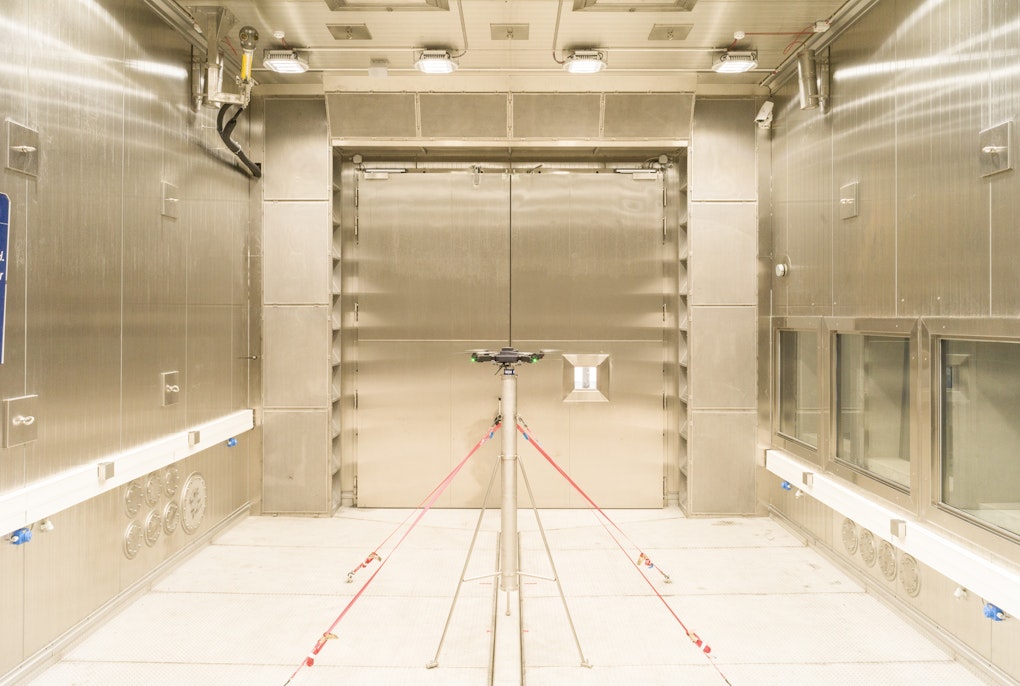

In the terraXcube's icing research tunnel, drones fly through freezing cold clouds

In Eurac Research’s terraXcube, an enormous 18 meter-long metal tube rears up like a cobra expelling icy breath. At temperatures as low as -20°C, a fine mist of water is released from the tube to investigate the effects of icing on drone rotors: an occurrence that can severely impair how drones and helicopters function. Water droplets can cool to well below freezing point in the clouds and still remain liquid, only freezing when they come into contact with a solid object, significantly altering the aerodynamic properties of rotors and helicopter blades. The consequences can be fatal.

Carrying out tests in such conditions can be very dangerous and highly risky due to the difficulties mentioned above. However, complex technical infrastructures that can generatemist indoors at temperatures below 0°C offer a solution. One of these ‘icing research tunnel’ was developed in terraXcube and co-financed by the Swiss Air-Rescue Rega. The first trials were carried out in 2021, and an extensive series of tests were carried out in February.

Ice impedes rescue flights

The idea of equipping Eurac Research’s extreme climate simulator with this infrastructure and building an icing wind tunnel in Bolzano came from a request from Rega. Drones are used to locate missing persons – or more precisely their cell phones – in rough mountain terrain. Using drones can save precious time in guiding rescue teams working in close cooperation with the police to the scene of the accident. The drone flies over the area where the person they are looking for is believed to be.

However, this sophisticated research can fail due to weather: icy conditions, such as low temperatures in clouds or snowfall, can adversely affect the efficiency of rotor blades and impair flight. For this reason, neither drones nor helicopters are allowed to take off in these conditions. Data from Switzerland shows just how critical the weather is for air rescues, particularly in the Alps where currently around 600 people a year cannot be treated from the air due to bad weather: a serious matter for the missing or injured people.

As the rotating elements are particularly affected by icing conditions, Rega is working intensively on the development of a de-icing technology that ensures that no ice can accumulate on the rotor blades. The aim of the terraXcube tests is to prove that this newly developed technology is fully functional even under the most severe conditions, as required by the European Aviation Safety Agency’s EASA CS-29 regulation.

The initial test results have been promising and there is a good chance that flight tests will soon be able to take place in the open air making it possible to equip rescue drones with the anti-icing system that enable flight in difficult conditions.

The DRONE-AED project: Can drones equipped with defibrillators save lives?

Just how disastrous rotor icing can be for drones was demonstrated in some tests undertaken by a Eurac Research team led by Senior Researcher at terraXcube, Ricardo Parin. After a very short time, the rotor blades of the drones being tested in the icing research tunnel, as part of the DRONE-AED project, were encrusted in a thick layer of ice: the flight had to be aborted after just two minutes, barely preventing the drone from crashing and being damaged. Riccardo Parin explains: “This test shows how dangerous these conditions are. For this reason, helicopters as well as other types of aircraft, are only allowed to fly with the appropriate certification for icing conditions. As far as the helicopter sector is concerned, very few models that are certified.”

The use of unmanned drones can open new possibilities for rescue missions. As part of the Drone AED project, a team from the Institute for Mountain Emergency Medicine, the Center for Sensing Solutions and terraXcube are researching this topic together. Drones can shorten the time it takes to start treating a cardiac arrest in mountain rescue missions by flying an automated external defibrillator (AED) to victims who could not otherwise be reached in a reasonable amount of time. This also involves determining the range of the MAVTech drone carrying the AED under various and extreme conditions. As expected, the effect of icing was dramatic and severely impaired the drone’s airworthiness within a very short time after it had been immersed in the freezing cold cloud of the icing wind tunnel.

Ice on rotor blades - a previously unknown variable

Ice on the rotor blades increases the weight of the drone and thus the energy consumption that the drone has to expend to fly. Ice also impairs its aerodynamics. Even if an ice encrusted drone does manage to stay in the air, it consumes much more energy and its range is drastically reduced. The layer of ice that covers the drone also changes the shape of the propeller blades and thus its performance. “The design and shape of the propeller blades are well-kept industrial secrets,” says Riccardo Parin. “The ice destroys their aerodynamic properties.” If the ice varies the shape and surface of the blades, a decisive factor for the quality of a drone is lost.

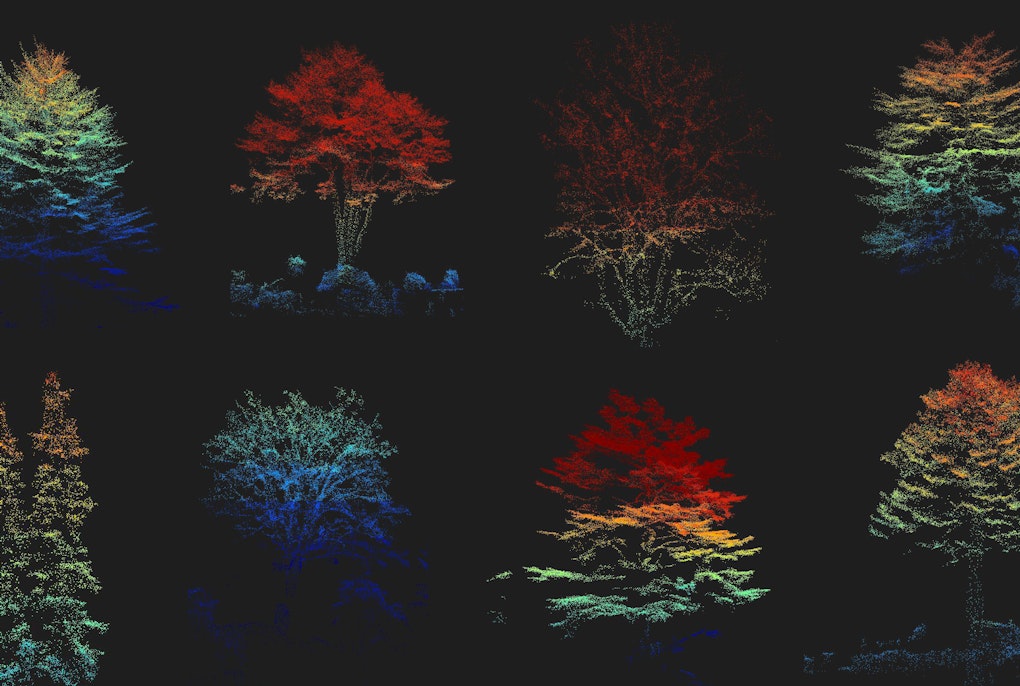

But what do we know about the ice that forms on the propellers of drones or UAVs (unmanned aerial vehicles) as they are also called, when they fly through freezing cold clouds? Very little. Riccardo Parin explains: “There are very few icing research tunnels and they are complicated and expensive to use. Even rarer are those with the right characteristics to test a complete UAV in the way we’re able to in terraXcube. Due to this, computer simulations are usually used to study the phenomenon of ice formation on fixed wings or rotor blades. These experimental tests provide an idea of the shape and properties of the ice under the conditions of the clouds simulated in the laboratory.” A 3D scanner from SolidWorld makes it possible to capture the surfaces of objects: in this case the ice layer on the rotor blades. The scanner then creates a 3D model. This is interesting because different types of ice – in terms of surface structure and density, can form depending on the conditions.

Depending on the temperature, the water droplets either freeze immediately on first contact with an object or slide a little over its surface before they solidify. This gives the ice different structures and density, depending on how much air was trapped during the freezing process. The 3D models of the ice make it possible to provide a complete characterization of the phenomenon.

“Our long-term goal is to use the data we collect thanks to the tests in the icing wind tunnel to characterize the different types of ice that can form during icing. We would like to validate and develop software for correct simulations of icing occurrences in a similar way to the Polytechnic University of Milan’s Polimice,” says Parin.

Where different research fields come together

Parin coordinated a team of scientists from the University of Padua and the Polytechnic Universities of Turin and Milan in carrying out the tests in terraXcube’s icing research tunnel and collaborated with unibz for a ‘month of ice’. The diverse applicability of this infrastructure can also be seen from the various study types it underwent: a sensor was tested that measures the size of water droplets in the air and characterizes the cloud type produced by the icing research tunnel. In addition, for the first time, an indoor flight of a drone in icing conditions was undertaken and different tests were carried out to study the effectiveness of hydrophobic substances used to prevent the formation of ice.

The terraXcube is also a partner of the Marie Skłodowska-Curie project TRACES – their claim: training the next generation ice researchers. In the project network, 15 scientists from various universities are conducting interdisciplinary research for their PhD projects on the complex topic of icing and risk mitigation for aircraft and engines. Next fall, the icing wind tunnel will be set up in the terraXcube for another time and the innovative infrastructure will be engaged to collect more data under controlled conditions with the aim of making flying even safer.